的主要用途与介简:/Purpose and introduction

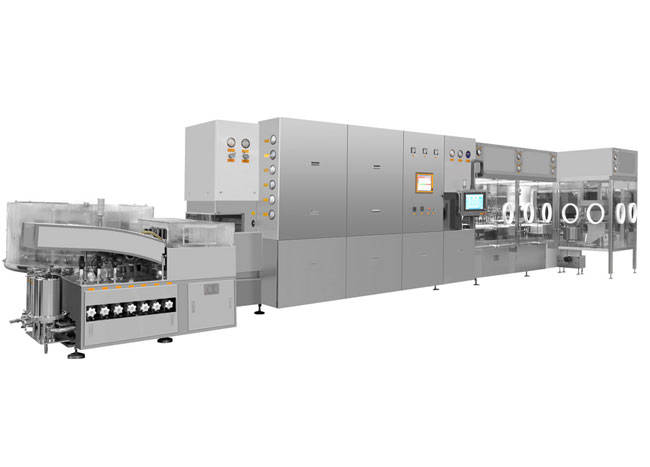

西林瓶介质透明液体洗烘包装线线加塞三级联动线由 QCL 系统立柱式彩超波洗瓶机、 ASMR铁路隧道式暖风重复往复灭菌处理处理烘干箱箱、NFGF系统型西林瓶介质透明液体包装线线加塞飞机机组成,也可手机单机动用。选广泛用于2-25ml外形尺寸的西林瓶水针的种植。能到位自喷灌水、彩超波粗洗、瓶内侧壁水清洗道路、瓶内侧壁接连2次重复往复水清洗道路、两次吹气、两次新鮮水清洗道路、接连2次吹气、瓶内侧壁吹气、点火、烘干箱灭菌处理处理去热原、蒸发、前空气、、包装线线、后空气、、加塞等二十几道制作工序。NLGF2-25 schering bottles liquid washing drying filling barging linkage line consists of QCL series vertical ultrasonic bottle washer, ASMR tunnel hot air circulation oven, NFGF electro schering bottles liquid filling barging into a crew, and also can be used stand-alone. Used in the 2-25 ml specification schering bottles of water production. Can finish the spray water injection, ultrasonic thick bottle washing, the outer wall of water flushing, bottle wall continuous secondary circulating water flushing, a blowing, a fresh water rinse, two consecutive bottle blowing, blowing the outer wall, preheating and drying sterilization before going to pyrogen, cooling, inflatable, filling, after filling, stoppering, etc more than 20 procedures.亮点:/characteristic

◆洗瓶机用机戒手夹瓶,实用多种多样尺寸规格的西林瓶;Bottle washer adopts manipulator clamp bottle, is suitable for a variety of specifications of schering bottles;◆洗瓶主要采用水雾喷针往返定位跟踪加上模式,的洗涤使用效果最好的,节电能量。并设立针架防会抖装Reciprocating mixer washing bottle with water spray needle track insert way, cleaning effect is good, save energy. Shake with needle frame◆洗瓶另一水汽蒸汽管道、喷针齐全独立空间分开单独进行,不要了交叉式空气污染,合适GMP想要想要;Mixer washing bottle the water pipe, injection needles completely separate, to avoid the cross contamination, in line with the GMP requirements;◆洗瓶机出瓶螺母式前可以加装部件实现降低块,有爱护螺母式,增多碎瓶用途;Pieces out of the bottle inside the screw before adding buffer block, protect the screw, reduce broken bottle;◆洗瓶机出瓶用一体化进口量同样带,联系拨瓶块输送带安瓿,正常运行固定可信度;Pieces out of the bottle inside the whole import synchronous belt, the connection piece of conveying ampoule bottle, operation is stable and reliable;◆烘干箱采取制热无限循环采暖器,温湿度不匀,低碳;Oven adopts hot air circulation heating, temperature uniformity, energy saving;◆烘干箱应设防莫名关机保护的实用功能,加载平安;Mixer oven has suddenly loses power protection function, safe operation;◆恒温干燥箱可配不断循环油冷平横装置,不耗损卧室功率,以减少卧室的压力不平横的风险性,降低温度的功效好;Mixer oven can match circulating water cooling device, not loss room air volume, reduce the risk of differential pressure imbalance in room, cooling effect is good.◆烘烤箱可配风压差大一键和平调控设计,减轻主卧室和烘烤箱的风压差大不和平可能会导致的高溫段倾斜,分装间洗烘间温度因素升高教一系的毛病;Mixer oven can match the differential automatic balance adjustment system, reduce the room and high temperature oven pressure difference caused by the imbalance of period of migration, filling between wash between baking temperature and so on a series of problems;◆烘干箱现有DOP加测标准接口(属于静压,风量,颗粒a粒子加测口);Mixer oven with DOP test interface (including wind pressure, wind speed, dust particle detection);◆真空烘箱降温段可带高压蒸汽灭菌功效(FDA特选);Mixer oven cooling segment with the function of sterilization (FDA selected);◆烤箱网带可带彩超牵连CIP迅雷在线擦拭模式;Type mixer oven mesh belt with ultrasound scanning CIP online cleaning system;◆烘烤箱内腔可来全方向、多视场角进行高压水清洁;In pieces inside the oven cavity can be all-round, multi-angle high-pressure water flushing;◆装罐机采取平均水平一起带的运瓶摸式,有着极运行速度,所以分瓶明确,变更尺寸规格件便宜;In pieces filling machine adopts horizontal synchronous belt bottle mode, high speed, and bottles of accurate, replacement of a convenient;◆塑料瓶子底优势的车辆运输水平线和岗位灶面很多定的间距,极为有利的于百级层风流的依据,必免呈现乱流感染药液;In pieces at the bottom of the bottle in the transport plane and work table there is a certain distance, is advantageous to the best level layer by wind, turbulence prevents pollution solution;◆灌装线机加塞一部分,使用程度送塞,各种程度圆筒吸塞,遵循了解有利,装料有利,送塞高速路的属性;Pieces filling machine gasser part, USES the level to plug, and horizontal disc vacuum plug, are convenient to observe, loading convenient, to plug the characteristics of high speed;◆包电脑装机可配瓷器泵、不锈钢圆管泵、蠕动消化泵;In pieces filling machine can match ceramic pump, stainless steel pump, peristaltic pump;◆分一键装机无瓶止灌,无瓶不放塞功用;In pieces filling machine no bottle filling, no bottle no gasser function;◆装灌机要选配系列伺服装灌方法(台达、三菱PLC、斯耐德)。In pieces filling machine optional servo filling forms, mitsubishi, schneider (Taiwan).◆整线应用PLC总有效控住、变频柜器、接触屏有效控住高技术,使用平稳稳定;接触屏可屏幕上显现各手机单机的使用动态展示,各有效控住点的出水量、空气压力、风压气压、热度等屏幕上显现,各转换开关状态下和内部故章屏幕上显现,内部故章个人程度和内部故章分折及排查技术,使一整个产出过程中可达自动式化有效控住,联线包括三机电气稳定平衡设施, 保障产出平衡稳定。The whole line adopts PLC control, inverter, touch screen control technology, the operation is stable and reliable; The operation of the touch screen can display the single machine dynamics, the control points of hydraulic pressure, air pressure, air pressure, temperature, etc, according to the switch state and fault display, fault self-diagnosis and fault analysis and elimination method, make the whole production process automation control, on-line has the compressors control balancing device, ensure production is balanced.要根据朋友的须得,还可供选用:According to the needs of customers, but also available for selection:◆西门子装置、德力西、三菱数控装置、台达等茶叶品牌设定装置;Pieces of Siemens, schneider, mitsubishi, Taiwan brands such as control system;◆水、气压力差、温度及超声检查波效果、尘土水粒子、风力上线检则、报警声音、见证、彩打系统;Pieces of water, gas pressure, water temperature and the intensity of ultrasonic, dust particles, wind speed on-line detection, alarm, record and print system;◆ORABS、CRABS、灭菌屏蔽器平台的。◆ORABS、CRABS、灭菌屏蔽器平台的。Mixer ORABS, CRABS, aseptic isolator system. Mixer ORABS, CRABS, aseptic isolator system.技術基本参数/technical parameters:

食品型號 product model | QCL60+ASMR620/35 | QCL60+ASMR620/43 | QCL60+ASMR620/43 | QCL80+ASMR620/48 | QCL120+ASMR800/55 | QCL120+ASMR1250/60 | QCL80*2+ASMR1250/60 | ||||||

采用技术参数 Cutting dimension(ml) | 2-25(国际上西林瓶) | 2-25(展览西林瓶) | 2-25(亚太西林瓶) | 2-25(亚太西林瓶) | 2-25(世界西林瓶) | 2-25(国家西林瓶) | 2-25(国际金西林瓶) | ||||||

灌装生产线头数 Fillingheads | 4 | 6 | 8 | 10 | 12 | 20 | 24 | ||||||

制造特性production capacity(pcs/h) | 120(7ml) | 180(7ml) | 200(7ml) | 300(7ml) | 400(7ml) | 500(7ml) | 650(7ml) | ||||||

洗瓶通过率Washing bottle percent of pass(%) | ≥ 99 | ≥ 99 | ≥ 99 | ≥ 99 | ≥ 99 | ≥ 99 | ≥ 99 | ||||||

洗瓶损毁率Washing bottle breakage(%) | ≤ 0.1 | ≤ 0.1 | ≤ 0.1 | ≤ 0.1 | ≤ 0.1 | ≤ 0.1 | ≤ 0.1 | ||||||

高压蒸汽灭菌平均温度sterilizing temperature(°C) | 300-350 | 300-350 | 300-350 | 300-350 | 300-350 | 300-350 | 300-350 | ||||||

通风量exhaust air rate (m3/h) | 3000 | 3000 | 4100 | 4100 | 7500 | 8,000-10,000 | 8,000-10,000 | ||||||

灌装生产线计算精度Filling accuracy(%) | ≤ ±2.5 (机器式带动水比热容泵、工业陶瓷泵、不锈钢材质泵) &n🌼bsp; ≤ ± 0.5-1.0 (电机驱使器驱使容积怎么算泵) | ||||||||||||

加塞优秀率Gasser percent of pass(%) | ≥ 99 | ≥ 99 | ≥ 99 | ≥ 99 | ≥ 99 | ≥ 99 | ≥ 99 | ||||||

新鲜空气层流整洁度Laminar air cleanliness(Class) | 100 | 100 | 100 | 100 | 100 | 100 | 100 | ||||||

真空体抽速Vacuum pumping speed(m3/h) | 10 | 30 | 50 | 60 | 60 | 100 | 120 | ||||||

电解电容量capacitance | 66.6 | 75.6 | 75.6 | 106.6 | 106.6 | 212.6 | 232.6 | ||||||

交流电源power supply | 385V 50Hz | 385V 50Hz | 385V 50Hz | 385V 50Hz | 385V 50Hz | 385V 50Hz | 385V 50Hz | ||||||

总质量total weight (kg) | 6300 | 6300 | 7900 | 7900 | 9400 | 10900 | 14600 | ||||||

外观形状长宽比boundary dimension(LxWxH) (mm) | 8,550 × 2,540 × 2,330 | 8,550 × 2,540 × 2,330 | 9,620 × 2,540 × 2,330 | 9,620 × 2,540 × 2,330 | 10,280 × 3,230 × 2,360 | 12,730 × 2,600 × 2,620 | 11,790 × 5,700 × 2,620 | ||||||

-

18217001818

18217001818

-

shnalong@aliyun.com

shnalong@aliyun.com

-

杭州纳庆机械性机器有效单位

杭州纳庆机械性机器有效单位

中文

中文  English

English